The Covered aluminium steel wire by compression, internationally known as Aluminium Clad Steel (ACS), is a wire of high resistance whose cover is carried through an extrusion process, that adheres the aluminuim by pressure and heat. The obtained product has a layer of covering of at least 10% of the total wire radius, and not less than 25% of its whole cross-section. Once the covering process is finished, the wire is drawn until its final diameter without any alternation in the aluminium steel ratio. Its properties combine high relation resistance-weight, what it makes of this product the best solution for electrical applications.

Due to its characteristics, this product is used extensively in the cable industry for the manufacturing of Optical Ground Wire (OPGW), conventional stranded earth wires and steel reinforced cores for phase conductors, all to be used in overhead lines. Also it can be used in alternative applications as helical hardware for overhead lines or those where the resistance to the corrosion is an important factor.

According to main international standard (IEC- 1232, EN-61232 and ASTM B-415), ACS wire is classified in 4 types based an aluminium cladding thickness.

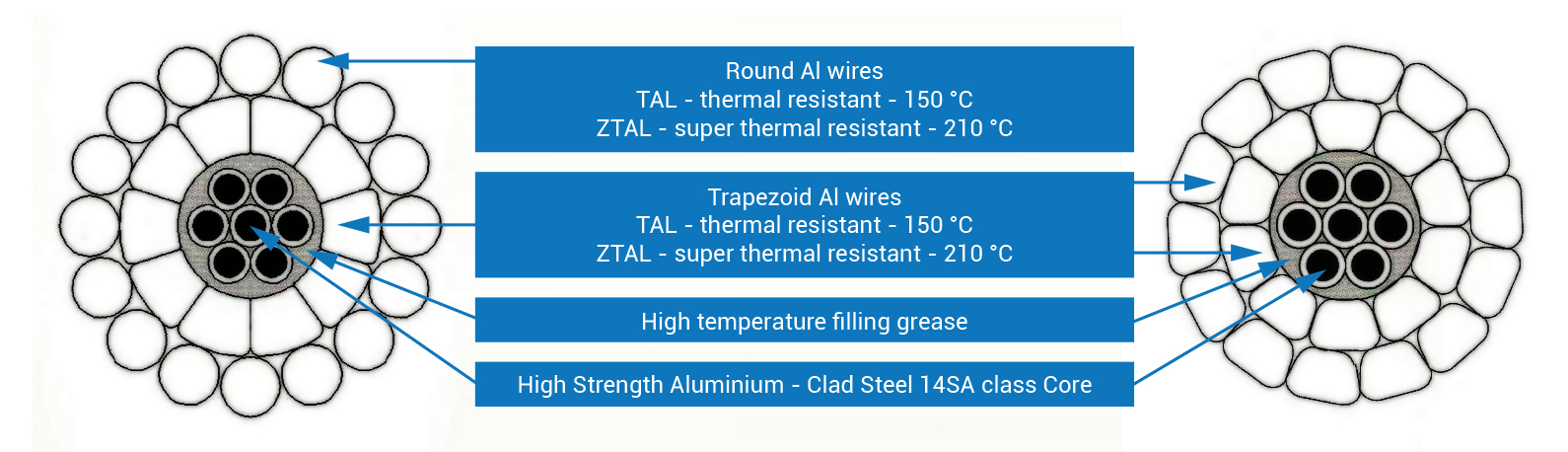

The inner layer is constructed with trapezoidal wires that contain a high-strength Aluminum-clad steel core, creating a gap filled with high temperature-resistant grease. Outer aluminum layers can be trapezoidal or round as necessary.

Functionality of the low sag conductor is based on the lower coefficient of thermal expansion of the steel core with respect to the outer aluminum layers. Sagging of the conductor is achieved by tensioning the steel core only while keeping the mechanical layers stress-free.

As a result of this sagging method, the coefficient of thermal expansion of the whole conductor at any temperature higher than the sagging temperature will be equal to that of the steel core.

Our supplier produces aluminium tube around fibre optic bundles which are used as essential part of OPGW cables.

The use of aluminium tube for these applications provides important advantages:

High corrosion resistance

Perfect sealing of fibre optic against water penetration

Great energy dissipation in electrical discharges

There are two different claddings on fibre optic types:

Aluminium tube over a care compound of fibre optic bundles

Aluminium tube over stainless steel tube containing fibre optic

According to customer packaging requirements the wire is then supplied on spools, in drums, in coils or on hats / coil carriers.